Our company has20 years experience

-

Call us anytime

+93 (0) 788 999935

-

Business Hours

Sat - Thur 08.00 AM to 04.00 PM

-

Email us now

info@khansteel.af

Complete Portfolio

Most of finished steel products portfolio from a supplier in region optimal efficiency in purchasing. Controlled weight tolerance per unit length to increase effective area and optimize consumption.

Certified Material

Certificate of quality for each consignment Customization of products Ability to customize and produce special products on basis of customers needs.

Customer Relationship Management

Responsiveness goes beyond the usual customer relationship principles provide services to facilitate work in the implementation.

Carbon Capture Unit

We are determined to build accompany here in Afghanistan, which is recognized for quality, reliability, excellence in, health and safety performance which makes a positive contribution to the community in which it operates air pollution and their treatments are one of the major issues in metal industries. The large scales, treatment of these unwanted dust particles has to be carried out as they cause big environmental problems.

Weak infrastructural facilities and lack of advanced technologies are the other factors causing air pollution. In Khan Steel we strictly follow effective housekeeping techniques and unique atmospheric condition contribute to active dust control plans.

We know the cause of dust formation, the characteristics of the dust and the source of dust emission so that we apply the system to control factors that causes dust and hazardous release.

In the beginning of Khan Steel mill, we installed two plants of high-quality dust collection system and retention filters they are designed with automatic system to extract dust, odour and smoke from the production unit environment via air extraction.

Time to time inspection, exhaust ventilation and dumping mechanisms are the factors that result in the complete control over the dust hazard.

We are aiming to evaluate potential benefits and possible challenges of the investments in the carbon dioxide capturing and utilization process in order to achieve efficient scale of emission reduction.

Air Filtering/Purifying Capacity & Expenses

200,000 cubic meters /24 hrs.

Carbon powder collection: 2000 kg/ 24 hrs.

Power Consumption: 1000 kw/ 1Megawatt/ hour.

Process cost AFN171,500 (2250 USO approx.)/ 24 hrs.

Support Required

Carbon Capture industrial unit of KSM needs continuous support of line governmental departments, climate change and protection organizations and funds.

This support will enable the sector to have latest technological options for carbon engineering and re-use application.

Khan Steel Mills CCU unit warmly welcomes experts and organizations to join the efforts to help the sector in converting the collected carbon to a valuable commodity which is currently a challenge.

We are dumping the collected carbon for now as of not having any promising option for re-use which will be turned to new headache for the steel industry. We call on Environment Protection agencies to support KSM`s CCU unit to map out potential organizations and experts to brainstorm on possible re-use of collected carbon.

Currently at Environmental Care Department of KSM, we are constantly following the global carbon engineers innovation in chemical, fertilizer and concrete mixing sector to adapt the possible option in Afghanistan.

We are sure that our effort will lead to success which will help the steel industry in Afghanistan to contribute to the climate protection through carbon emission control and re-use mechanism.

We are hoping and expecting Carbon engineering experts to help KSM in building the capacity of Afghans to be able to re-use collected carbon in a promising sector with the technical collaboration of the carbon market initiatives.

Safety

We endeavor to avoid negligence through our safety management system to ensure a safe workplace for our employee and achieve zero LTl or fatality.

The Process of Creating Ultimate Strength

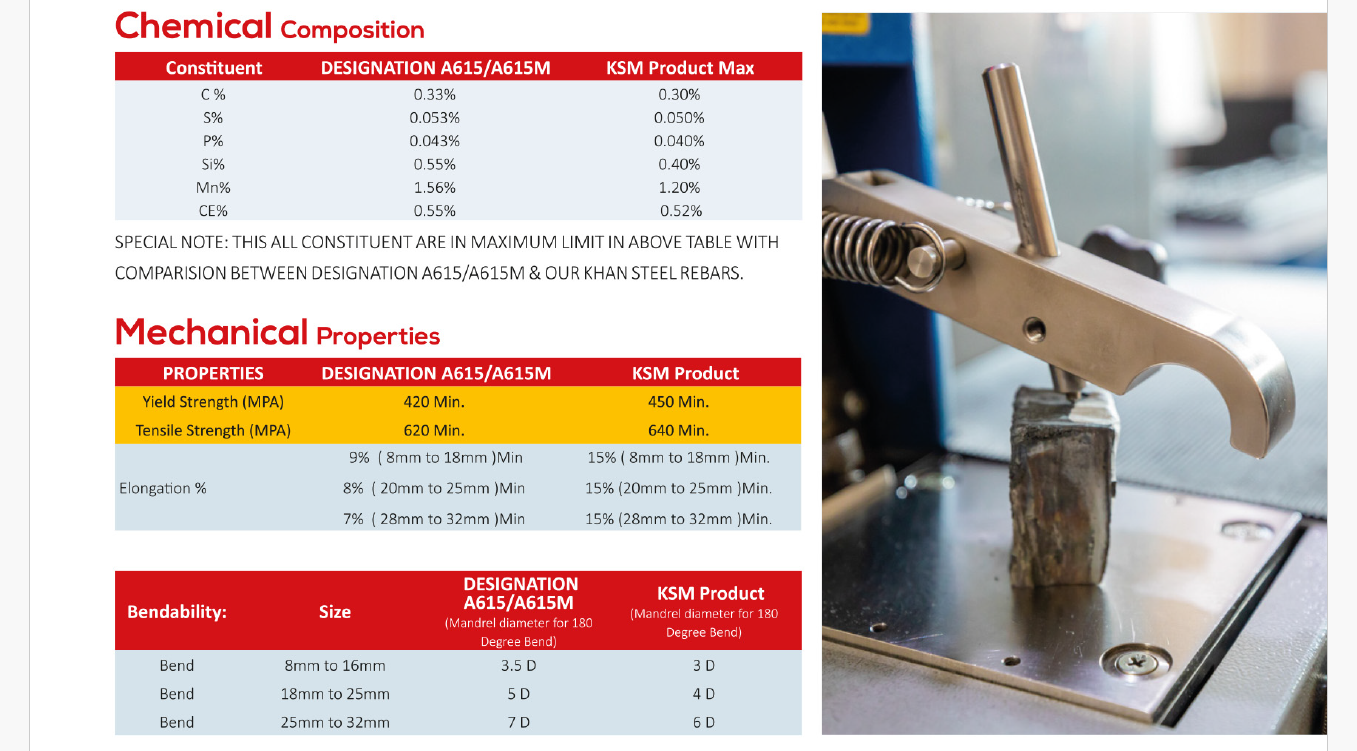

Chemical Composition & Mechanical Properties

We are committed to extending our factory

Dari

Dari